JESENTECH GROUP CORPORATION

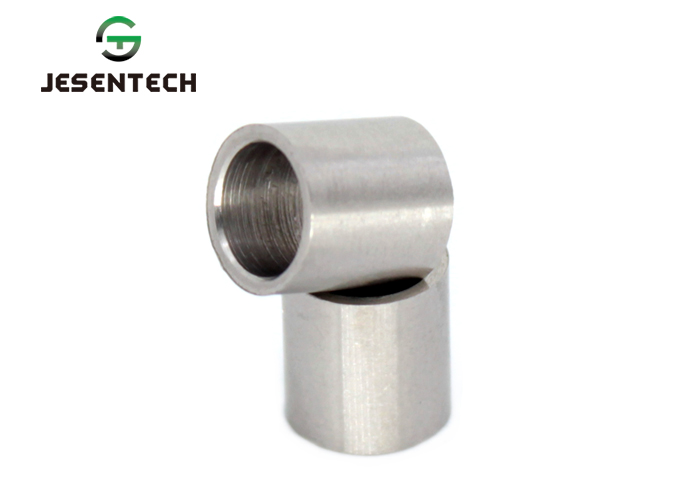

JESENTECH GROUP CORPORATION is a manufacturer of special-shaped

shaft fastener R & D and system Made with well-equipped testing

facilities and strong technical force.

With a wide range, good quality, reasonable prices and stylish

designs, our products are extensively used in Automation equipment,

robotics, medical treatment, automobiles, marine railways, bridges,

buildings, structures, tools, instruments, instruments, etc. and

other industries.

Our products are widely recognized and trusted by users and can

meet continuously changing economic and social needs.

The products we can produce and process are Locating/Positioning Pins/Cylindrical Pins/Lead/Slide

Screw/Bushings/Linear Shafts/Plungers Screws/Screws and

Bolts/Nuts/Circular/Hexagon Posts/Washers/Floating

Joints/Cantilever shafts/Knurled Knobs/Screws/Air Tool /Quick

Couplers etc...

We welcome new and old customers from all walks of life to contact

us for future business relationships and mutual success!